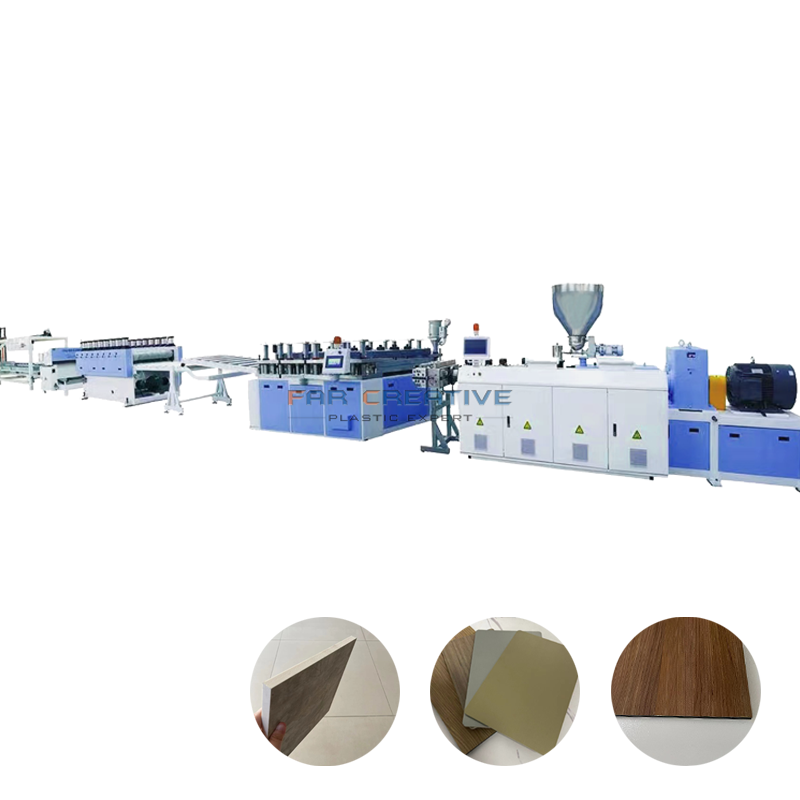

It is not adhesive PVC decoration film, magnetic powder brake. Film is put tighted by air swelling rollers, four-working stations. Using flattening roller to make the PVC decoration film smooth and flat, without any air bubbles. With infrared film adjusting system and tension adjust system to keep the film flat, smooth and non-deformation.

MYHou

MYHou